- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

- Size: 45cbm

- Place of Origin: China

- Brand Name: DG

- Model Number: DG65-II DG75-III DG85-III

- Weight: 8000.000 kg

- :

- :

- :

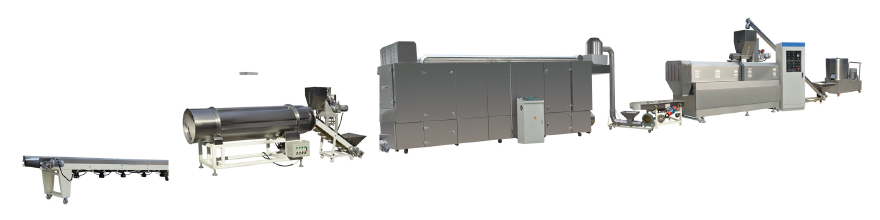

Automatic Fish Feed Extruder Production Line

Brief introduction of Dog/ Cat /Fish /Pet Food processing line:

............................................................................................................................................................

With our new technology of combination screws,our twin screw extruder production line is applied to produce

different pet food with various raw material and nutrient elements.The production technology parameters are controlled precisely.

Through extruding,the degraded protein is easy to absorbed.Meanwhile ,with relevant palatability supplementary project,

the production process can fulfill the chewing feel of pets.

1.Raw material :Meat bone meal,Corn Powder,Soybean meal,Fish Meal,Wheat Flour etc

2. Products: All kinds of Pet food /Cat food /Dog food with different shapes and types.

3. Capacity: 100-150 KG/H,200-300KG/H ,350 -500KG/H,800-1000 KG/H

4. Flow Chart: Mixing —Extruding —Spreading and Cooling —Drying — Flavoring—Cooling—Packaging

5. Voltage: Three phases: 380V/50HZ, Single phase: 220V/50HZ,

also can make it according to customers' local voltage of different countries

6. Machines Materials: All the machines are made by food grade stainless steel.

Features of Pet food /Cat food /Fish food /Dog food Twin Screw Extruder :

1. Different combination ways of different screws can produce differnent products

2. Various dies can produce various shapes pet food.

3. Touch screen to control ,easy to operate .

4.Cooling ,heating feeding flavoring system controled by touch screen

5. Different extruder produce different throughout /capacity

Technical Parameters of pet pellet food making machine/production Line :

| Model | Installed power | Power consumption | Throughput | Dimension | Application |

| DG65-II processing line | 61KW | 46KW | 100-150kg/h | 25.8X3X2.4M | Dog food fish feed cat food |

| DG75-III processing line | 79KW | 59KW | 200-300kg/h | 27.5X3X2.7M | Dog food fish feed cat food |

| DG85-III processing line | 120KW | 90KW | 250-500kg/h | 28.5X3.3X3.5M | Dog food fish feed cat food |

| DG90-I processing line | 165KW | 123KW | 800-1000kg/h | 30X3.3X3.5M | Dog food fish feed cat food |

Our Service & Turnkey Solution

a.) Consultation service before, during,and after sales;

b.) Project planning and design service;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

e.) Training of equipment maintenance and operating personally;

f.) New production techniques and formulas;

g.) Provide 1 year complete warranty and life-time maintenance service.

About us :Jinan DG machinery co.,ltd in China:

We: Jinan DG machinery co.,ltd located in Jinan ,Shandong Province ,China, is the professional manufacturer of

Snack food processing machinery.We specialize in this field for may years ,not only can supply with the entire machiner

design,but also can modify the production line to meet client's demand.All kinds of patents , proprietary technology ,

breakthrough and certificated .

There is a testing center in our factory which combined experiments,dmonstration andtrainingin one facility.We also

can test new technical experiments according to customer requirements .

Our extrusion systems are widely used in:puffed snack food,breakfast cereals,corn flakes ,nutritional artificaila rice,

textured or fibre protein food,pet food,aquatic feed,modified starch,bread crumbs and other snack food.

- Size: 45cbm

- Place of Origin: China

- Brand Name: DG

- Model Number: DG65-II DG75-III DG85-III

- Weight: 8000.000 kg

- :

- :

- :

Model | Total Power | Power consumption | Capacity | Dimension |

DG65-II line | 61kw | 46kw | 100-150kg/h | 26000x3000x2800mm |

DG70 line | 72kw | 54kw | 200-250kg/h | 27000x3000x3000mm |

DG85-IV line | 139kw | 104kw | 400-600kg/h | 29000x3000x3100mm |

DG52-II line | 72kw | 54kw | 100-150kg/h | 24000x3000x2800mm |

DG75-II line | 110kw | 82.5kw | 200-300kg/h | 26000x3000x3000mm |

DG75-VIII line | 151kw | 113kw | 400-600kg/h | 28000x3000x3100mm |

DG90 line | 343kw | 257kw | 600-800kg/h | 33000x4200x3100mm |